Designing New Ways to Make Use of Ocean Plastic

Ian Lambert explores different options for re-using the plastic clogging the world's oceans.

Beachcombing has long been a part of life for island communities. On the southwestern edge of Scarp, a small, treeless island off the coast of Harris in Scotland’s Outer Hebrides, the Mol Mòr (“big beach”) was where locals went to collect driftwood for repairing buildings and making furniture and coffins. Today there is still much driftwood, but as much or more plastic.

Scarp was abandoned in 1972. The island is now used only in summer by owners of a small number of holiday homes. But across Harris and the Hebrides, people continue to make practical and decorative use of beachcombed plastic items. Many homes will have a few buoys and trawler floats hanging on fences and gateposts. Black plastic PVC pipe, in plentiful supply from fish farms wrecked by storms, is often used for footpath drainage or filled with concrete and used as fence posts. Larger pipe can be split lengthways to make feeder troughs for the famously hardy highland cattle.

Rope and netting are used as windbreaks or to prevent ground erosion. Many islanders use fish boxes – large plastic crates washed ashore - for storage. And there is a small craft industry that repurposes found objects as tourist souvenirs, turning plastic tat into anything from bird feeders to buttons.

But this beachcombing, recycling and re-use of larger plastic items does not even scratch the surface of the problem. The smaller fragments of plastic that are harder to collect are more likely to enter the food chain, or be drawn back into the sea. Storms cutting away at riverbanks often reveal an alarming plastic geology, with layers of plastic fragments in the soil several feet below the surface.

Reports indicating the scale of plastic pollution of the world’s oceans have become widespread in the past ten years, with the final episode of the BBC’s Blue Planet II in 2017 with David Attenborough marking a high-water point of recognition of the problem. Estimates of the amount of plastic entering the oceans each year range from 8m tonnes to 12m tonnes, although there is no way of accurately measuring this.

It is not a new problem: one of the islanders who has spent 35 years holidaying on Scarp said that the variety of objects found on Mol Mòr had diminished since New York City stopped dumping rubbish at sea in 1994. But a reduction in diversity has been more than matched by an increase in quantity: the BBC Radio 4 programme Costing the Earth reported in 2010 that plastic litter on beaches had doubled since 1994.

Old problems, new methods

Growing awareness of ocean plastic has prompted local efforts to keep beaches clean. But the amount of discards collected poses the question of what to do with it. Ocean plastic photo-degenerates with long exposure to sunlight, sometimes making it difficult to identify, and difficult to recycle as it is contaminated with salt and often with sea life growing on its surface. Some recycling methods can be successful only with a maximum ratio of 10% ocean plastic to 90% plastic from domestic sources.

Local groups sometimes work together to collect large amounts plastic from the beaches, but for local authorities the challenge is how to deal with a problematic material that is hard or impossible to recycle. The alternative is landfill with an £80 per tonne fee. Lecturer and jewellery-maker Kathy Vones and I examined the potential to re-use ocean plastic as the raw material for 3D printers, known as filament.

For example, polypropylene (PP) can be easily ground down and shaped, but has to be mixed 50:50 with polylactide (PLA) to maintain the consistency the printer requires. Mixing types of plastics like this is a step backwards, in the sense that they become more difficult to recycle, but as an investigation into new potential uses for the material, what we’ve learned might allow us to take two steps forward in the future. Other ocean plastics such as polyethylene terephthalate (PET) and high-density polyethelene (HDPE) are also suitable.

Ocean plastic, turned into filament for use in a 3D printer. Ian Lambert, Author provided

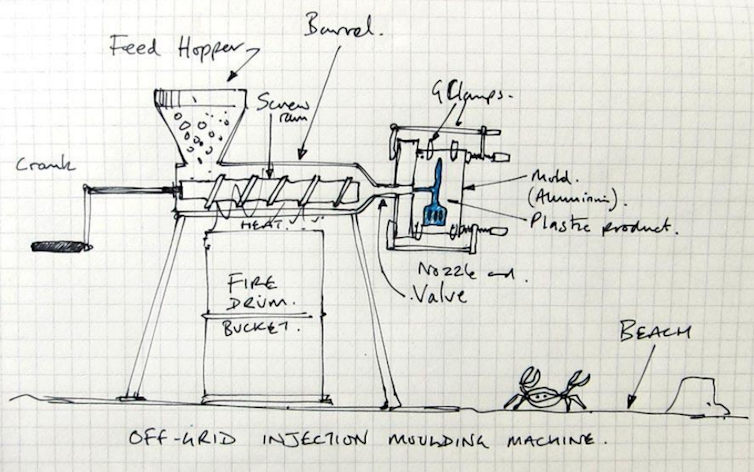

Another approach I looked at was to melt polypropylene rope over a bonfire and use it in an improvised injection moulding machine. But this technique had problems with accurately maintaining the correct temperature, and toxic fumes.

Design for an off-grid, bonfire-powered, foraged-plastic-fuelled injection moulding machine. Ian Lambert, Author provided

The Dutch inventor Boyan Slat’s Ocean Clean Up project has been much more ambitious, aiming to retrieve 50% of the Great Pacific Garbage Patch in five years with a large net suspended from an inflatable boom that draws catches the plastic and draws it into a collection platform. However, the project has run into difficulties, and will in any case collect only larger fragments at the surface. It is estimated that the majority of ocean plastic is particles less than 1mm in size suspended in the water column, with yet more plastic sinking to the ocean floor.

These will require fresh solutions. Removing the vast quantities of plastic in the environment is a vexing problem that will be with us for centuries. We need conscientious joint efforts from politicians and industry and fresh ideas – all of which are currently lacking.

Ian Lambert, Associate Professor of Design, Edinburgh Napier University.

This first appeared on:

Image credit: Susan White/USFWS, CC BY via Flickr